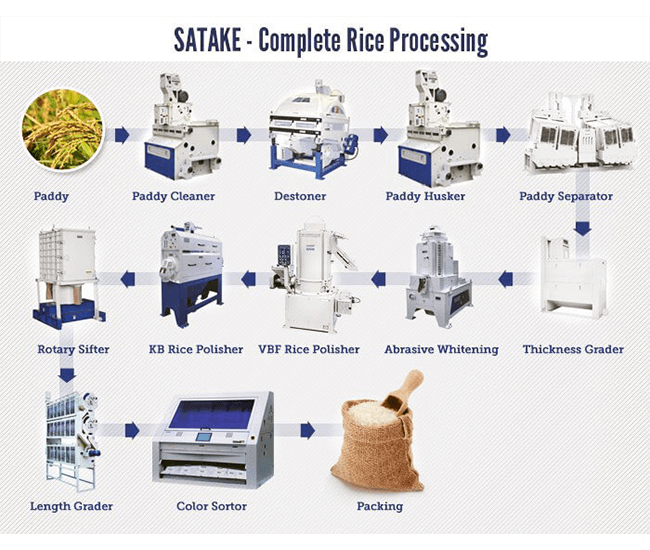

Rice processing machinery from field to table. How can we help you?

Satake designs and manufactures the most comprehensive range of machines, processes and instrumentation for the rice sector. This equipment encompasses cultivation, harvesting, storage, primary and secondary processing of varieties of rice produced throughout the world.

“Satake’s expertise both as the world’s leader in rice processing equipment and experts in cereal grinding are combined to provide custom designed solutions for rice flour production.”

Paddy Cleaner: The Satake Paddy Cleaner is an all purpose separator designed for the efficient separation of large coarse material and small fine materials such as grit during the cereal cleaning process. The Cleaner can be adapted for use as a Silo Intake Separator and is also compatible with an Aspirator unit or with a Hopper at the stock outlet.

Destoner: The Satake Destoner separates stones and heavy impurities from grains, utilizing bulk density differences. Rigid, heavy-duty construction with thicker steel plates and a sturdy frame ensures long life. This is the ideal machine for separating stones from grains in an effecient, trouble-free manner.

Paddy Husker: Satake has incorporated its unique technologies into the new Paddy Husker for superior performance.

Paddy Separator: The Satake Paddy Separator is an oscillation-type paddy separator with a very high sorting performance and an easy maintenance design. All varieties of rice such as long grain, medium grain and short grain can be sorted easily and accurately. It separates a mixture of paddy and brown rice into three distinct classes: paddy mixture of paddy and brown rice, and brown rice. To be sent to a husker, back to the paddy separator and to a rice whitener, respectively.

Rotary Sifter: The Satake Rotary Sifter incorporates a completely new design with many first-time features developed out of years of experience and improving techniques. The machine can sift milled rice efficiently and accurately into 2 – 7 grades: large impurities, head rice, mixture, large brokens, medium brokens, small brokens, tips, bran, etc.

Rice Polisher: The Satake Rice Polisher cleans the surface of rice, significantly enhancing the quality of finished products. The machine has achieved an excellent reputation in many countries for its high performance and for the innovations which have been incorporated over the past 30 years.

Vertical Rice Polisher: The Satake Vertical Rice Polisher series of vertical friction rice whitening machines incorporates the most advanced technologies available and has proved to be superior to competitive machine in rice mills throughout the world. The versatility of the VBF for milling rice of all degrees of whiteness with minimum brokens makes it the ideal machine for modern rice mills. It’s processing capability ranges from all kinds of rice (long, medium, and short) to other cereal grains such as maize.

Vertical Abrasive Whitener: The Satake Vertical Abrasive Whitener range of machines incorporate the most advanced techniques of vertical milling and has been proven to be superior to similar machines in rice mills throughout the world. The versatility of the Satake machines for milling rice of all degrees of whiteness with the minimum brokens makes it the ideal machine for modern rice mills.

Thickness Grader: The Satake Thickness Grader was developed for the most efficient separation of broken and immature kernels from rice and wheat. The screens are selectable from a wide range of available slot sizes.

Length Grader: The Satake Length Grader separates one or two kinds of broken or shorter grains from whole grain by length. Broken grain or shorter grain which is more than half of the whole grain in length cannot be separated using a sieve or thickness/width grader.

Color Sorter: The Satake Color Sorter inspection machine rejects foreign materials, off-color and other bad product that are mixed in with grains of rice or wheat. Using lightning and high resolution cameras, the software identifies defective product and ejects the “rejects” by using small air nozzles at high velocities.