What Is Optical Sorting?

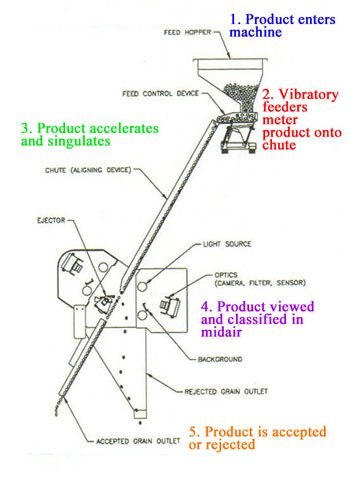

Specially designed optical filters narrow the reflected light into specific wavelengths that accentuate the difference between the acceptable product and the product to be rejected. Specialized CCD, IR, UV, or RGB (full color red/green/blue) cameras receive the reflected light from the product and send this information to be amplified and classified.

Utilizing the user interface, the operator programs in the parameters for acceptable product and product to be rejected. Once the machine determines that an object falls outside the acceptable parameters, a high speed ejector is activated at the precise time the product passes the ejector nozzle. The good product continues in a straight line and the rejected product is removed from the good stream.

2. Vibratory feeders meter product onto chute

3. Product accelerates and singulates

4. Product viewed and classified in midair

5. Product is accepted or rejected

Satake understands how important food safety is, and today – over 80 years after we first introduced the electronic color sorter – it is still at the core of our company values. Satake machinery uses precise electronic color and shape inspection to increase the quality of product to meet the continuously increasing demand of today’s consumer.

Each of our current machines; the EVOLUTION, FMS2000, NIRAMI, BELTUZA, the plastic PELLET SORTER, FMSR-IR and the BELTUZA-SPECTRA and VANTAGE (“EZ” series) are tailored to specific markets based on capacity, cost, and machine dimensions – among other unique features. These sorters are proven in many industries in monochromatic, bichromatic, trichromatic, and full color applications in both visible and infrared wavelengths.

1931 ►Incorporation of “Electric Sorting Machine Company” in Lowell, Michigan.

1932 ►Installation of machines for commercial sorting of Michigan beans. The world’s first color sorters.

1934 ►Development of automatic equipment for sorting of blanched peanuts.

1935 ►First successful installation of automatic sorting machines in the blanched Virginia peanut industry.

1937 ►Developed a sorting machine based on a two-color principle of selection.

1940 ►Installed first bowl feed sorting machine.

1941 ►First successful installation of two color sorting machine for Idaho peas.

1947 ►Installed two color sorting machine for green coffee beans in Colombia, South America.

1952 ►Introduced color sorting machine for green coffee into South Africa.

1953 ►Introduced gravity feed machines for the sorting of lemons, apples and other similar products.

1956 ►Changed name to Mandrel Industries Inc. and started expansion and diversion program. Entered field of

geophysical instrumentation by acquisition of ElectroTechnical Labs, Inc., Houston. Company relocated to Houston, Texas.

1957 ►Formed ELEXSO Corporation to sell sorting machines overseas.

1960 ►Electric Sorting Machines (ESM) tested a harvester-mounted color sorter for tomatoes, but it wasn’t until the early 1970’s when price of tomatoes skyrocketed that we began selling harvester-mounted color sorters.

1964 ►Became a subsidiary of the Ampex Corporation, a diversified oil field equipment/service company.

1970 ►Geosource purchased “ESM” from Ampex. Introduced the MEGASORT line of multi-channel slide machines. Installed hundreds of machines into the peanut and rice industry.

1978 ►Shipped more than 100 MEGASORTS 38-channel. Also developed the GB line of bichromatic machines making an

instant impact on Central American coffee industry.

1980 ►3 Vision Systems product line became the successor to the GB line and continued to find success in the peanut and coffee industry.

1984 ►ESM was acquired by ODISTA, which was led by Pat Childress.

1986 ►Introduction of Shell-ex, the first sorter to use infrared technology which revolutionized the pecan, almond and walnut industries.

1992 ►ESM was purchased by the Satake Corporation.1993 ►Introduced the ScanMaster, the first high volume, high-resolution CCD camera, and broad slide color sorter.

1995 ►Expanded the ScanMaster line with the introduction of an infrared version and a range of sizes.

1996 ►Introduced the GridMaster length/shape sorter.

1997 ►Introduced the ColorMaster Belt Sorter in both visible and IR versions.

1999 ►Introduced the SeedScan, seed maturity laser sorter based on chlorophyll fluorescence. Introduced the ScanMaster II, expanding the operator interface and communication capabilities of the ScanMaster product line.

2000 ►Expanded the ScanMaster product line with the introduction of a UV sorter.

2001 ►Introduced the ScanMaster Jumbo, capable of running large products such as macadamia nuts, in-shell almonds,

large pecan halves, among others.

2002 ►Introduced the PelletScan, a high resolution optical sorter specially designed for plastic pellets.

2006 ►Satake USA moved to a new 64,000 sq ft larger purpose built factory in Stafford, TX.

2007 ►Introduced the AlphaScan, a compact, low cost, high capacity color sorting machine.

2010 ►Introduced the EVOLUTION RGB, a full color sorting machine that uses 16 million colors, high-resolution cameras and long lasting LED lighting.

2012 ►Introduced the Plastic PELLET SORTER, with much greater optical resolution than the previous model.

2013 ►Satake USA’s Western Operations moved to a new facility in Modesto, CA.

2014 ►Introduced the cost-effective, compact and portable PIKASEN Alpha FMS-2000 full color sorter.

2015 ►Satake USA moved the Corporate Headquarters to a new 130,000 sq ft office and warehouse facility in Stafford, Texas USA. Introduction of the highly affordable, high capacity optical sorter line the REZS. Model sizes 2500, 4500 and 6500 ideal for pulses, rice and other similar grain types. The Satake EVOLUTION MIR multi-wavelength sorter is launched in North America. Ideal for removing foreign material.

2016 ►Introduced the enhanced PIKASEN Alpha FMS-2000 “Feeder” version that has a vibratory feeder system and also sorts by size and shape. The North America release of the new Satake belt sorter, the BELTUZA with sanitary stainless body construction and 650mm wide belt.

2017 ►The North America release of the new Satake belt sorter, the BELTUZA with sanitary stainless body construction and 650mm wide belt. The Satake “EZ” series of cost-effective, high capacity sorters, are revamped for sales in the Americas. There are now 3 models, the 2500 (3x240mm chutes), 4500 (6x240mm chutes), and 7500 (10x240mm chutes).

2018 ►The Satake RGBR optical sorter is introduced to the North American market. The RGBR features full color RGB cameras, size and shape detection, and infrared technologies.

2019 ►Satake begins selling the FMSR-L machine into Latin America countries. The FMSR-L is manufactured in Brasil using the lastest Japanese technology.