Bulk Weigher

Bulk Weigher

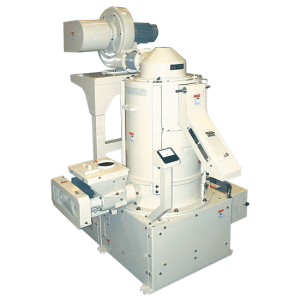

The Satake STBS Weigher is reliable compact machine of sanitary construction.

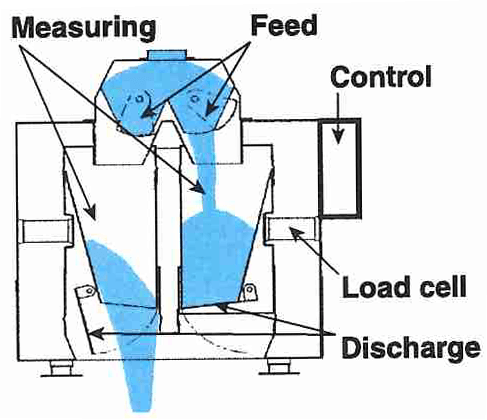

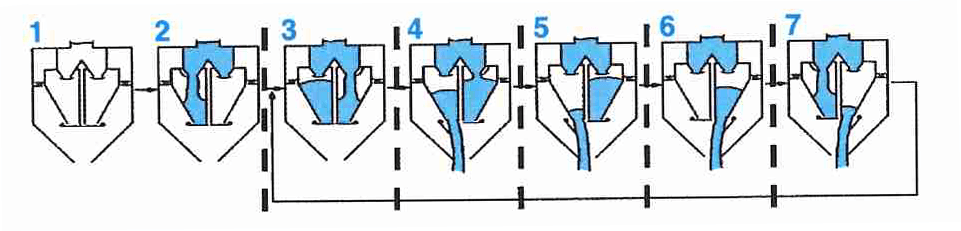

1. Incoming grain fills the first measuring hopper.

2.Then, incoming grain is diverted to the second hopper.

3.While the second hopper is being filled, the grain in the first hopper is measured and discharged.

4. Incoming grain is diverted to the first hopper.

5. The grain in the second hopper is weighed and discharged

The two measuring hoppers are thus alternately filled, measured and discharged and the accumulated weight and throughput are calculated.

| Model | STBS40C-T | STBS80C-T | STBS120C-T | STBS200C-T |

| Capacity | 20m3/h | 40m3/h | 60m3/h | 100m3/h |

| Accuracy | ±0.1%FS | |||

| Power Source | AC100±15 V(50/60 Hz) | |||

| Required Power | 100 W | |||

| Air Pressure | 0.4 Mpa | |||

| Air Volume | 15n1/min | 20n1/min | 80n1/min | 80n1/min |

| Ambient Temp. | 0~50°C | |||

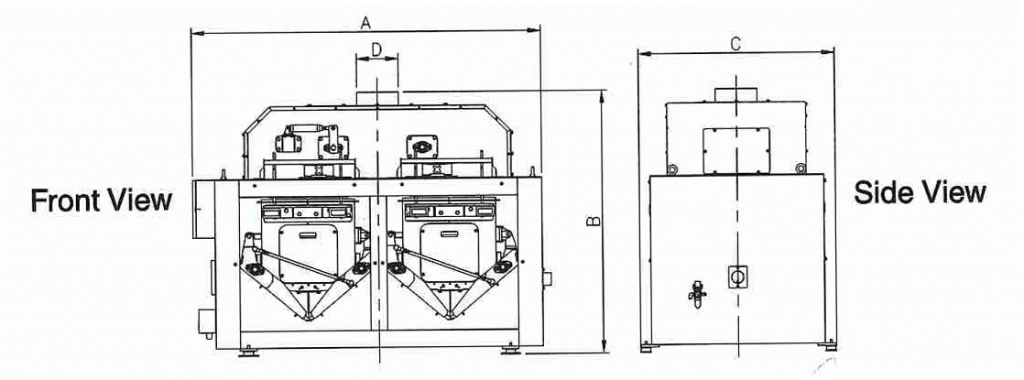

| Model | A (mm) | B (mm) | C (mm) | D (mm) |

| STBS40C-T | 1,035 | 1,140 | 790 | Φ154 |

| STBS80C-T | 1,271 | 1,417 | 967 | Φ200 |

| STBS120C-T | 2,100 | 1,417 | 1,212 | Φ250 |

| STBS200C-T | 2,100 | 1,920 | 1,212 | Φ306.4 |

1.Extremely accurate weighing for process control and monitoring.

2.Compact design requires less headroom for easier installation.

3.Can be used to control the flow rate of product.

4.Can be linked to central PLC for remote operation and monitoring.

All Satake products are the subject of continuous development and, as a result, their specification may change and differ in detail from those shown.